Actualités

17 avril 2024

Fin de session et recherche de stage

16 avril 2024

Gala d’excellence : recherche et enseignement 2024

11 avril 2024

L’ÉTS accueillera la 92ᵉ édition du Congrès de l’Acfas avec la collaboration de l’Université Concordia

11 avril 2024

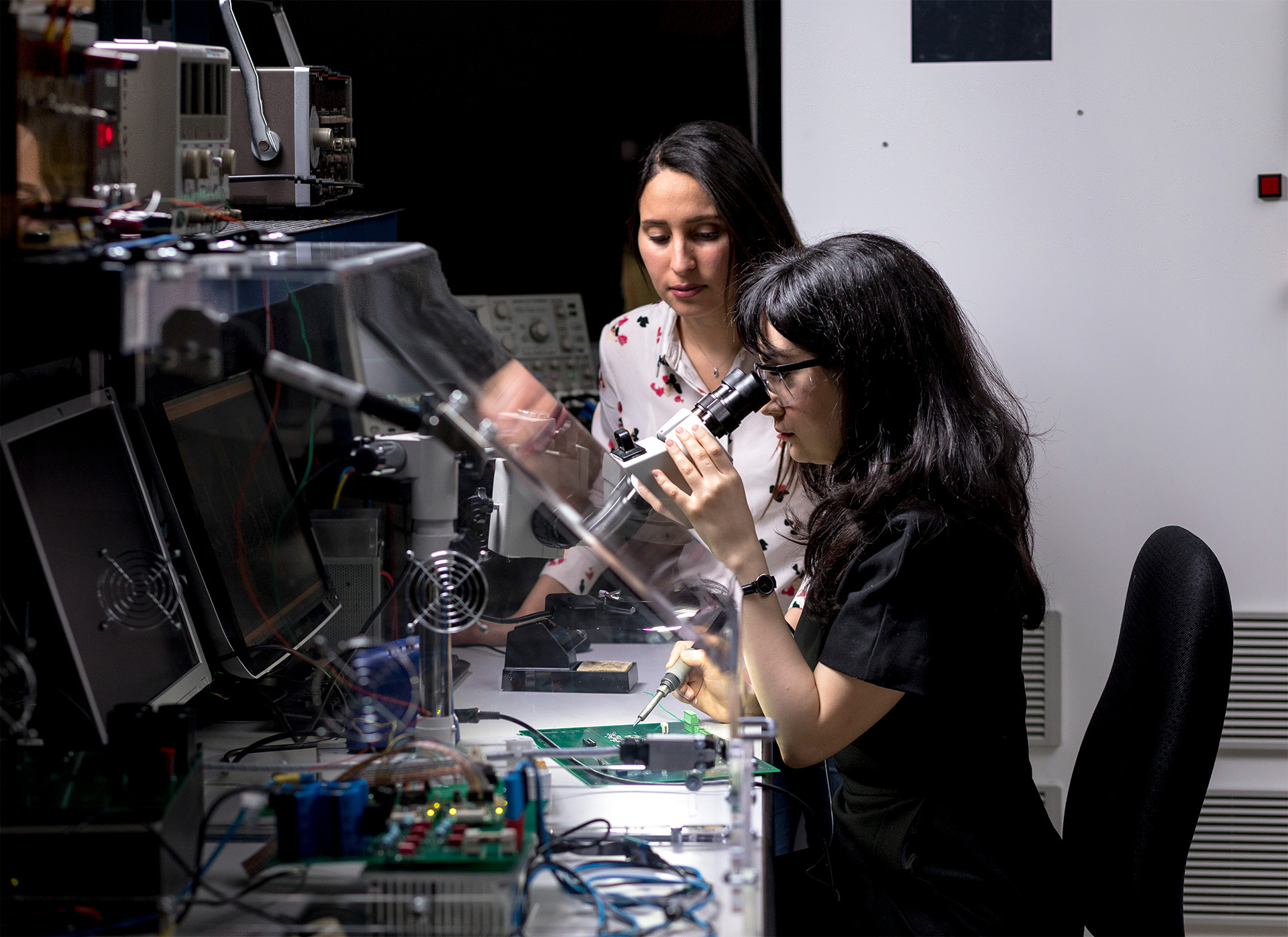

Journée francophone des femmes en informatique

1

Vous êtes actuellement sur cette page

2

Aller à la page : 2

3

Aller à la page : 3

...

51

Aller à la page : 51

Aller à la page suivante

Explorez votre avenir

universitaire