Prix et distinctions

Recherche et innovation

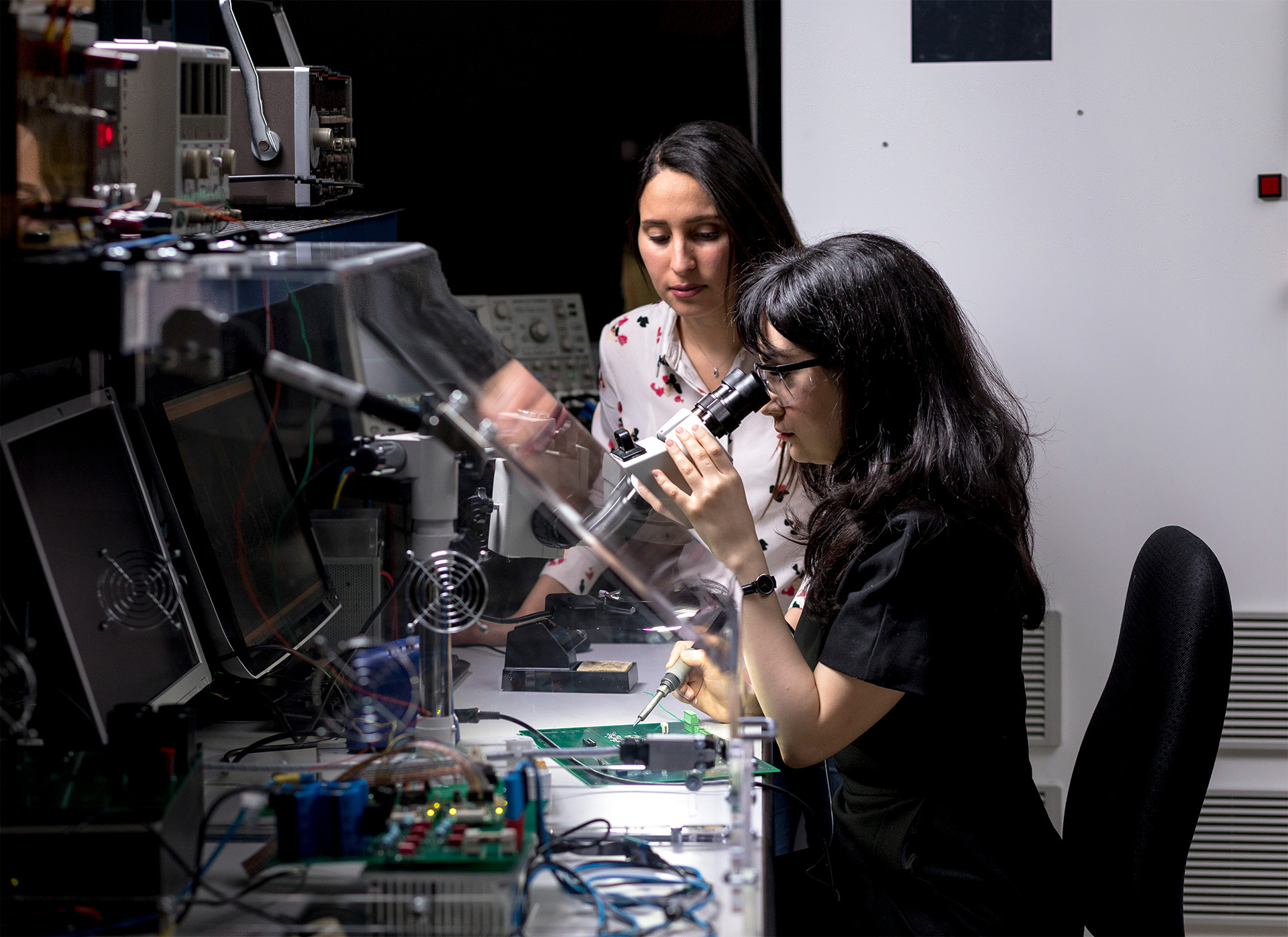

LARCASE – Laboratoire de recherche en commande active, avionique et aéroservoélasticité

Actualités

24 avril 2024

Programme NeuroFOCUS | Brisez l’isolement, restez actives et actifs et optimisez vos capacités!

23 avril 2024

La Feuille de route gouvernementale en économie circulaire au Québec saluée par l’ÉTS, le CERIEC, l’Institut AdapT et le RRECQ

17 avril 2024

Fin de session et recherche de stage

17 avril 2024

Des investissements importants à l’ÉTS pour développer la recherche appliquée en sciences quantiques

16 avril 2024

Gala d’excellence : recherche et enseignement 2024

1

Vous êtes actuellement sur cette page

2

Aller à la page : 2

3

Aller à la page : 3

...

51

Aller à la page : 51

Aller à la page suivante

Explorez votre avenir

universitaire