Actualités

11 avril 2024

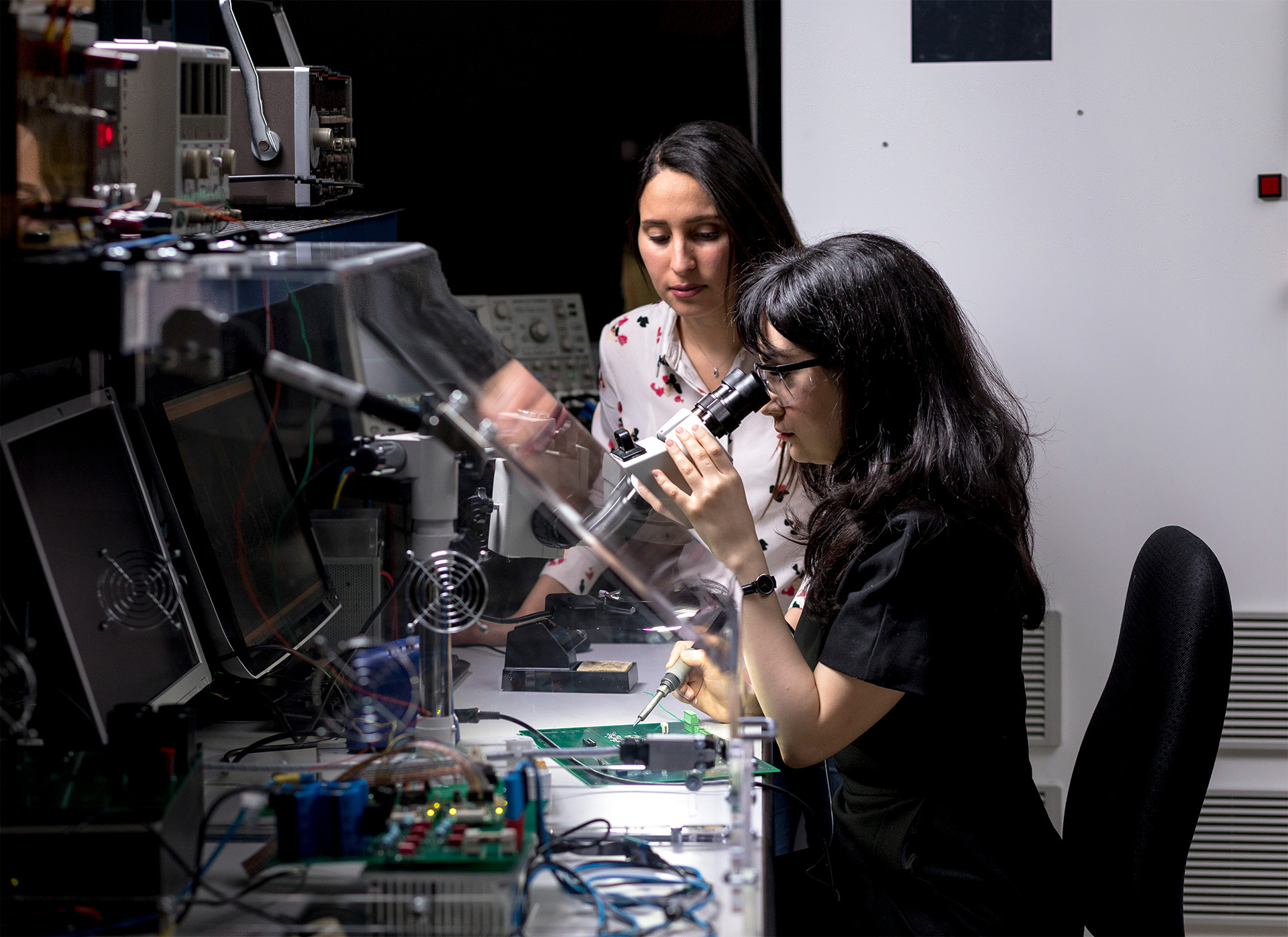

Journée francophone des femmes en informatique

10 avril 2024

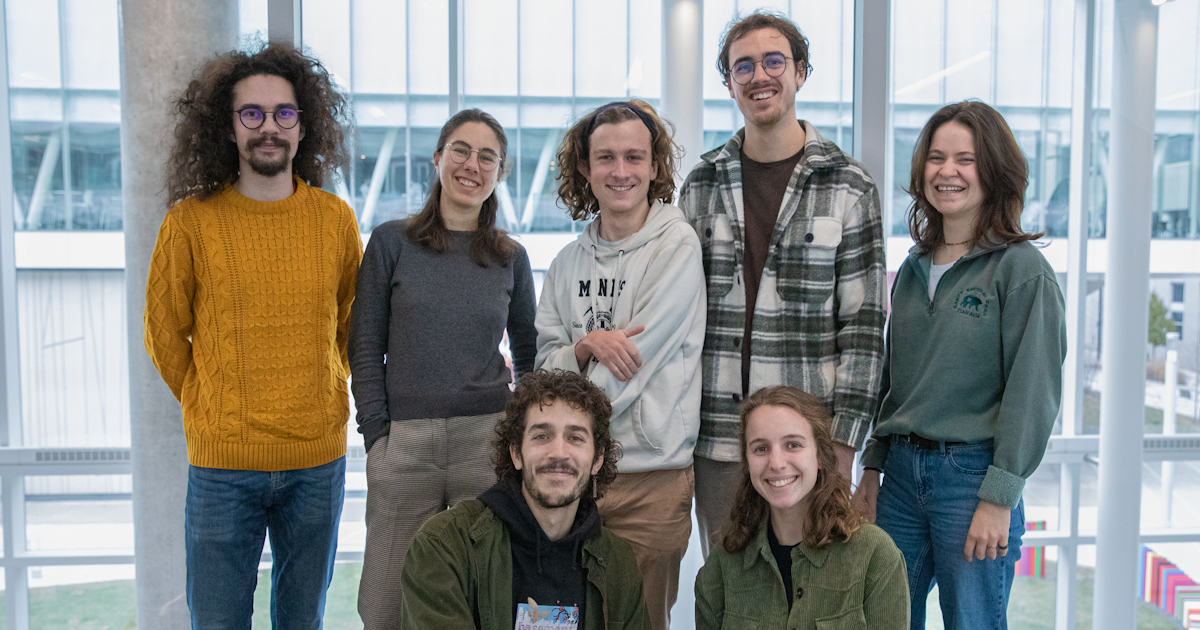

Dévoilement des lauréat(e)s de la 1ʳᵉ édition du programme de résidence artistique de l’ÉTS.

04 avril 2024

Dernier droit pour les stages de l'été 2024!

04 avril 2024

La DCI se classe 2e aux CS Games 2024!

02 avril 2024

Consignes entourant l’éclipse solaire du 8 avril 2024

28 mars 2024

Un Réveil Écologique et Solidaire recrute!

1

Vous êtes actuellement sur cette page

2

Aller à la page : 2

3

Aller à la page : 3

...

50

Aller à la page : 50

Aller à la page suivante

Explorez votre avenir

universitaire